Cutting Tool Life Calculation . Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of. • cutting tools undergo high force and temperature and temperature gradient. Position and angle of inclination in the tool life. • machining is accomplished by cutting tools. Each has an effect on. What is the relation between the. The taylor tool life equation is used to calculate the tool life of any type of cutting tool. How to calculate tool life. The formula for tool life typically takes the form of: By chipping due to mechanical breakage. Tool life (tl) can be measured using distance, in meters, number of holes, or in minutes. The three main machining parameters when turning are speed, feed, and depth of cut. How to improve tool life in turning.

from www.researchgate.net

Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of. How to calculate tool life. • machining is accomplished by cutting tools. How to improve tool life in turning. By chipping due to mechanical breakage. • cutting tools undergo high force and temperature and temperature gradient. What is the relation between the. The three main machining parameters when turning are speed, feed, and depth of cut. The formula for tool life typically takes the form of: The taylor tool life equation is used to calculate the tool life of any type of cutting tool.

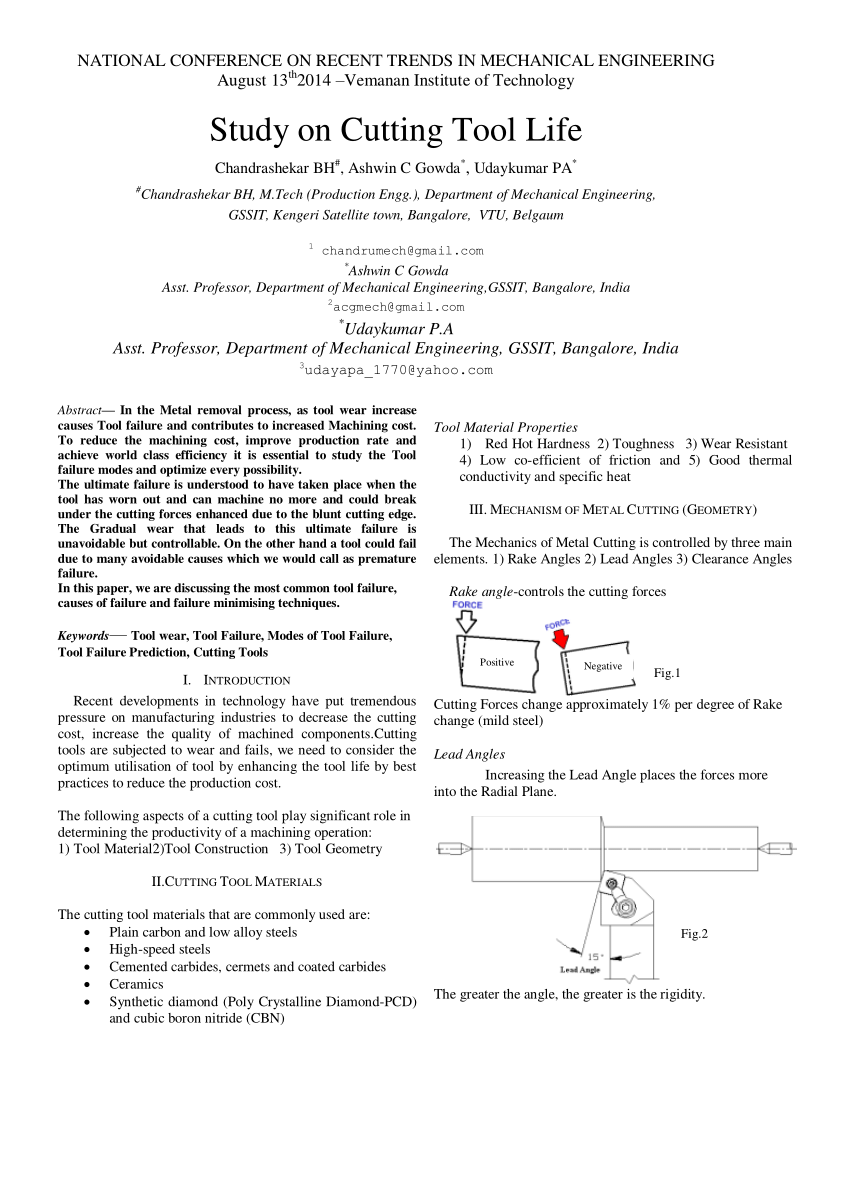

(PDF) Study on Cutting Tool Life

Cutting Tool Life Calculation The formula for tool life typically takes the form of: The taylor tool life equation is used to calculate the tool life of any type of cutting tool. Position and angle of inclination in the tool life. Tool life (tl) can be measured using distance, in meters, number of holes, or in minutes. The three main machining parameters when turning are speed, feed, and depth of cut. Each has an effect on. How to improve tool life in turning. Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of. What is the relation between the. • cutting tools undergo high force and temperature and temperature gradient. • machining is accomplished by cutting tools. The formula for tool life typically takes the form of: How to calculate tool life. By chipping due to mechanical breakage.

From entagalex.blogspot.com

TOOL LIFE Mechanical engineering Cutting Tool Life Calculation How to calculate tool life. • machining is accomplished by cutting tools. Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of. • cutting tools undergo high force and temperature and temperature gradient. Tool life (tl) can be measured using distance, in meters, number of holes, or in minutes. What is the relation. Cutting Tool Life Calculation.

From www.researchgate.net

(PDF) Study on Cutting Tool Life Cutting Tool Life Calculation Each has an effect on. By chipping due to mechanical breakage. Position and angle of inclination in the tool life. How to improve tool life in turning. The taylor tool life equation is used to calculate the tool life of any type of cutting tool. The formula for tool life typically takes the form of: Tool life (t) = constant. Cutting Tool Life Calculation.

From marinerspointpro.com

Types of Cutting Tool Materials Properties & Characteristics Cutting Tool Life Calculation By chipping due to mechanical breakage. How to calculate tool life. Tool life (tl) can be measured using distance, in meters, number of holes, or in minutes. Position and angle of inclination in the tool life. The formula for tool life typically takes the form of: Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f). Cutting Tool Life Calculation.

From www.chegg.com

Solved An engineer is interested in the effect of cutting Cutting Tool Life Calculation Tool life (tl) can be measured using distance, in meters, number of holes, or in minutes. Position and angle of inclination in the tool life. What is the relation between the. The formula for tool life typically takes the form of: The three main machining parameters when turning are speed, feed, and depth of cut. The taylor tool life equation. Cutting Tool Life Calculation.

From www.researchgate.net

(PDF) Methods of Improving Cutting Tool Life A Review Cutting Tool Life Calculation How to improve tool life in turning. • machining is accomplished by cutting tools. What is the relation between the. The formula for tool life typically takes the form of: How to calculate tool life. By chipping due to mechanical breakage. Each has an effect on. Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f). Cutting Tool Life Calculation.

From www.slideserve.com

PPT ME 350 Lecture 5 Chapter 22 & 23 PowerPoint Presentation ID Cutting Tool Life Calculation The formula for tool life typically takes the form of: • machining is accomplished by cutting tools. The taylor tool life equation is used to calculate the tool life of any type of cutting tool. Each has an effect on. Tool life (tl) can be measured using distance, in meters, number of holes, or in minutes. • cutting tools undergo. Cutting Tool Life Calculation.

From mavink.com

Tabel Cutting Speed Cutting Tool Life Calculation How to improve tool life in turning. • machining is accomplished by cutting tools. • cutting tools undergo high force and temperature and temperature gradient. Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of. What is the relation between the. How to calculate tool life. Position and angle of inclination in the. Cutting Tool Life Calculation.

From tru-edge.com

Tool Life Management TruEdge Cutting Tool Life Calculation • cutting tools undergo high force and temperature and temperature gradient. By chipping due to mechanical breakage. The formula for tool life typically takes the form of: Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of. Tool life (tl) can be measured using distance, in meters, number of holes, or in minutes.. Cutting Tool Life Calculation.

From www.machinemetrics.com

What is Tool Life? How to Optimize Tooling with Machine Data Cutting Tool Life Calculation By chipping due to mechanical breakage. What is the relation between the. • cutting tools undergo high force and temperature and temperature gradient. • machining is accomplished by cutting tools. The taylor tool life equation is used to calculate the tool life of any type of cutting tool. Tool life (t) = constant (c) / (cutting speed (v) * feed. Cutting Tool Life Calculation.

From www.numerical.minaprem.com

Taylor’s Tool Life Formula for Machining Cutting Tool Life Calculation • cutting tools undergo high force and temperature and temperature gradient. Each has an effect on. The three main machining parameters when turning are speed, feed, and depth of cut. By chipping due to mechanical breakage. • machining is accomplished by cutting tools. Position and angle of inclination in the tool life. How to calculate tool life. Tool life (t). Cutting Tool Life Calculation.

From www.researchgate.net

Tool life vs. cutting speed for selected tool material types [38 Cutting Tool Life Calculation • cutting tools undergo high force and temperature and temperature gradient. How to improve tool life in turning. Position and angle of inclination in the tool life. The three main machining parameters when turning are speed, feed, and depth of cut. • machining is accomplished by cutting tools. By chipping due to mechanical breakage. What is the relation between the.. Cutting Tool Life Calculation.

From slidetodoc.com

CUTTING TOOL TECHNOLOGY 1 Tool Life 2 Tool Cutting Tool Life Calculation The three main machining parameters when turning are speed, feed, and depth of cut. What is the relation between the. The formula for tool life typically takes the form of: Position and angle of inclination in the tool life. Tool life (tl) can be measured using distance, in meters, number of holes, or in minutes. How to improve tool life. Cutting Tool Life Calculation.

From www.slideserve.com

PPT ME 350 Lecture 5 Chapter 22 & 23 PowerPoint Presentation ID Cutting Tool Life Calculation The three main machining parameters when turning are speed, feed, and depth of cut. Each has an effect on. The taylor tool life equation is used to calculate the tool life of any type of cutting tool. What is the relation between the. The formula for tool life typically takes the form of: Position and angle of inclination in the. Cutting Tool Life Calculation.

From waykenrm.com

Feed Rate and Cutting Speed Difference in CNC Machining WayKen Cutting Tool Life Calculation How to calculate tool life. Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of. • machining is accomplished by cutting tools. The formula for tool life typically takes the form of: What is the relation between the. • cutting tools undergo high force and temperature and temperature gradient. Each has an effect. Cutting Tool Life Calculation.

From www.slideserve.com

PPT Theory of cutting Tool wear PowerPoint Presentation, free Cutting Tool Life Calculation The formula for tool life typically takes the form of: Tool life (tl) can be measured using distance, in meters, number of holes, or in minutes. Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of. By chipping due to mechanical breakage. Each has an effect on. How to improve tool life in. Cutting Tool Life Calculation.

From www.researchgate.net

Tool life at different machining conditions Download Table Cutting Tool Life Calculation How to improve tool life in turning. By chipping due to mechanical breakage. Position and angle of inclination in the tool life. How to calculate tool life. • cutting tools undergo high force and temperature and temperature gradient. The taylor tool life equation is used to calculate the tool life of any type of cutting tool. The three main machining. Cutting Tool Life Calculation.

From present5.com

Lecture 7 Machining Tool Life Wear and Failure Cutting Tool Life Calculation The taylor tool life equation is used to calculate the tool life of any type of cutting tool. The formula for tool life typically takes the form of: The three main machining parameters when turning are speed, feed, and depth of cut. • cutting tools undergo high force and temperature and temperature gradient. By chipping due to mechanical breakage. Each. Cutting Tool Life Calculation.

From www.youtube.com

Taylor's tool life equation In Metal cutting Example Problem YouTube Cutting Tool Life Calculation The three main machining parameters when turning are speed, feed, and depth of cut. The formula for tool life typically takes the form of: • cutting tools undergo high force and temperature and temperature gradient. Each has an effect on. How to improve tool life in turning. Tool life (tl) can be measured using distance, in meters, number of holes,. Cutting Tool Life Calculation.